The Vaasa-based Novafloor is a manufacturer, seller and supplier of floor coverings. A significant part of the company’s business consists of the surface treatment of their own products. A few years ago, problems began to surface in the company’s surface treatment production line’s automation software. Having to continuously sort out problems quickly started to disrupt production. Novafloor contacted CoE Group, who performed the needed software modifications. The line resumed operation as expected.

The joy of a functional line, however, was short-lived. In 2022, the company’s production facilities, including the newly refurbished line, were destroyed in a fire.

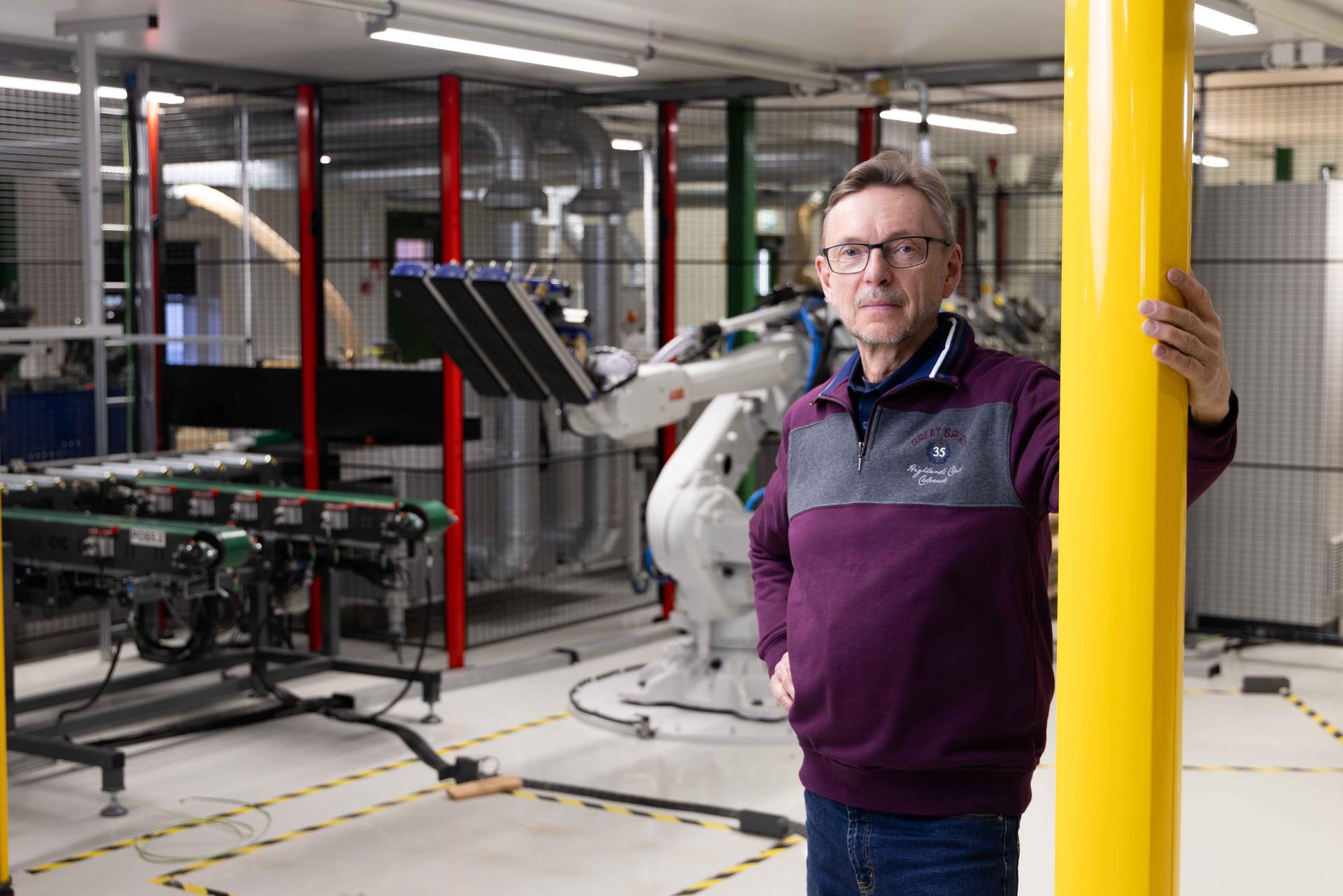

“After the fire, we started considering a new line supplier. During the modifications of the old line, we were extremely satisfied with CoE Group’s professionalism and the smoothness of our cooperation. With this trust and the expertise that CoE Group had gained from the old line, we didn’t even consider competing suppliers; we directly approached CoE Group for the new production line,” says Jarmo Myllymäki, one of Novafloor’s founders.

Turning a multi-stage, delicate process into an automatic, smooth system

Coe Group took charge of the layout design, mechanical engineering, electrical engineering and automation engineering of the new surface treatment line. The foundation for designing a functional line was the expertise and experiences both companies had gathered of the operation and challenges of the old line. Unique solutions were devised to achieve the optimal outcome in the design of the line.

According to Myllymäki, CoE Group’s expertise stood out especially in the way the company was able to take control of the design of such a large system. In the line, which comprises of several different devices and multi-stage processes, a robot picks up the boards onto conveyors and separates them. The boards are then individually directed to the staining line, where they are treated with various methods. Finally, another robot lifts the finished boards onto pallets for packaging. The technically complex line involves multiple functions, devices, machines and moving parts that must seamlessly integrate with each other. In the design of the line, potential problems and taking control of the line without damage in the case of such problems, has also been taken into account.

“The line can be compared to a tightly packed convoy of cars. You can imagine what happens if the first car suddenly brakes. The surface treatment carried out with the line is a delicate, precise and multi-stage process where no interruptions or disturbances are allowed. CoE Group’s expertise has therefore been particularly evident in ensuring the functionality of this large system, conveyor operation and programming, as well as in the mechanics of the line.”

CoE Group is an important strategic partner

Myllymäki is satisfied with the operation of the new line. After its commissioning, as expected, details have been refined to meet Novafloor’s needs even better. Myllymäki is pleased with CoE Group’s developmental approach and communication during and after the process.

“Strategically selected, reliable and skilled partners in various areas of business operations are vital for the success of a business. For us, CoE Group exemplifies this kind of partnership.”

Novafloor is a Finnish company that manufactures, imports and sells floor coverings. In addition to its own brand, Novafloor’s product range includes German parquets, planks, laminates and vinyls. The frames of Novafloor’s parquets are surface-treated in the company’s own production facilities. Novafloor was founded in 2007 and employs 20 people.

Get to know Novafloor

Read more about our services!

Electrical and automation engineering